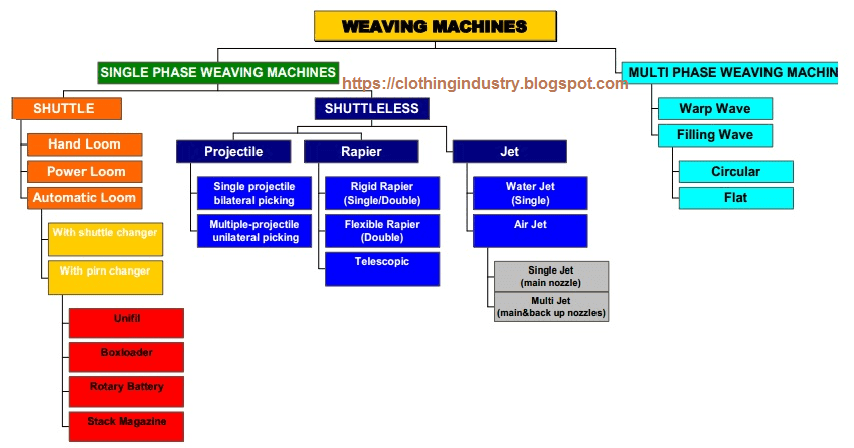

Different classification or types of weaving machines:

Weaving machines can be classified according to several characteristics:

- Nature of fabric formation;

- Method of weft insertion (picking) used;

- Type of shedding device used;

- Number of colours of the weft threads that can be used;

- Type of yarn used;

- Width of the woven fabric produced;

- Number of sheds simultaneously formed, along the warp on the weaving machine.

Let us now discuss these classifications:

1. The nature of fabric formation:

Most weaving machines carry out periodic formation of fabric. Each period can be considered as starting with the shed opening operation, followed by the insertion of the weft across the full width of the warp. The closing of the shed produces the required interlacing of the warp with the newly-inserted weft. The beating-up operation then consolidates the new weft into the fabric. The element of new fabric thus formed is then drawn off, and a fresh warp released into the weaving zone. Weaving continues as this sequence of operations is repeated.

There are also weaving machines which carry out continuous formation of fabric, where several weft threads are progressively inserted through a multiwave-shed, followed by an arrangement of ‘point beat-up’.

In the case of periodic formation, the shed is formed simultaneously across the full width of the warp. A single weft thread is then inserted across the full width of the warp and is followed by the beat-up operation.

This process is repeated periodically at a suitably high rate. The majority of weaving machine types fall into this category. These are also known as ‘single phase’ weaving machines (e.g. Sulzer, Dornier, Picanol, Vamatex).

In continuous formation, the shed is made in each of several groups or sections of equal width across the overall width of the warp. The opening and closing of the shed in successive groups is timed so that a number of picks equal to the number of groups of warp can be simultaneously conveyed across the warp. Thus, beating-up takes place progressively across the width of the warp, for each weft thread inserted. This category of weaving machine is described as ‘multiphase’ (e.g. Wasserman, Cerdans, Ruti, etc.).

2. Method of weft insertion (picking):

Shuttle weaving machines (e.g. Picanol) pick the weft thread into the shed by means of a shuttle which carries the weft package; shuttleless weaving machines use stationary thread packages positioned on one side of the warp, from which the weft is drawn through the shed by means of one of several different devices.

So, shuttleless weaving machines can be classifi ed according to the method of weft insertion (picking), as follows:

- Rapier weaving machines (Draper, Vamatex, Ruti, P–190, etc.);

- Projectile weaving machines (Sulzer, Novostav, etc.);

- Pneumatic (air-jet) weaving machines (Elitex, Sulzer, Nissan, etc.);

- Water-jet weaving machines (Elitex, Nissan, etc.);

- Pneumatic-rapier weaving machines (ATPR).

3. Type of the shedding device:

There are various shedding mechanisms available: cam, dobby or Jacquard.

4. The number of colours of weft threads that can be used:

There are single-colour (monoweft) and multicolour (multiweft) weaving machines.

5. Type of yarn:

Weaving machines are able to produce fabrics from a variety of yarns: cotton, wool, silk, fl ax, synthetics, glass, etc.

6. Width of the woven fabric produced:

Weaving machines can produce fabrics with working widths ranging from narrow (up to 120 cm) to wide (up to 5 m).

7. Number of sheds simultaneously formed along the warp on the weaving machine:

There are monoshed and multished weaving machines.

Additionally, shuttle weaving machines are classified according to:

- The method of weft replenishment: on automatic machines, the weft package (or shuttle, depending on the design of the machine) is replaced automatically in the event of weft breakage or depletion; and on non-automatic weaving machines, the weft package is changed manually;

- The construction of the picking mechanism: either middle- or bottom-picking;

- The number of shuttles used: monoshuttle or multishuttle.

The development of shuttleless weaving led to devising of other methods of picking the weft, for example, rapier picking, which is now widely used on modern weaving machines. Weaving machine manufacturers have generally identified their weaving machines by a combination of letters and numbers, but there is no common system with which to identify a machine’s type

The image above happens to be centered.

Source https://clothingindustry.blogspot.com

The image above, though 1200px wide, should not overflow the content area. It should remain contained with no visible disruption to the flow of content.

And now we’re going to shift things to the right align. Again, there should be plenty of room above, below, and to the left of the image. Just look at him there… Hey guy! Way to rock that right side. I don’t care what the left aligned image says, you look great. Don’t let anyone else tell you differently.

In just a bit here, you should see the text start to wrap below the right aligned image and settle in nicely. There should still be plenty of room and everything should be sitting pretty. Yeah… Just like that. It never felt so good to be right.

And just when you thought we were done, we’re going to do them all over again with captions!

The image above happens to be centered. The caption also has a link in it, just to see if it does anything funky.

The rest of this paragraph is filler for the sake of seeing the text wrap around the 150×150 image, which is left aligned.

As you can see the should be some space above, below, and to the right of the image. The text should not be creeping on the image. Creeping is just not right. Images need breathing room too. Let them speak like you words. Let them do their jobs without any hassle from the text. In about one more sentence here, we’ll see that the text moves from the right of the image down below the image in seamless transition. Again, letting the do it’s thang. Mission accomplished!

And now for a massively large image. It also has no alignment.

The image above, though 1200px wide, should not overflow the content area. It should remain contained with no visible disruption to the flow of content.

And now we’re going to shift things to the right align. Again, there should be plenty of room above, below, and to the left of the image. Just look at him there… Hey guy! Way to rock that right side. I don’t care what the left aligned image says, you look great. Don’t let anyone else tell you differently.

In just a bit here, you should see the text start to wrap below the right aligned image and settle in nicely. There should still be plenty of room and everything should be sitting pretty. Yeah… Just like that. It never felt so good to be right.

Imagine that we would find a use for the extra wide image! This image has the wide width alignment:

Can we go bigger? This image has the full width alignment:

And that’s a wrap, yo! You survived the tumultuous waters of alignment. Image alignment achievement unlocked! One last thing: The last item in this post’s content is a thumbnail floated right. Make sure any elements after the content are clearing properly.

Tinggalkan Balasan